- Home

- Development Themes : Development of an energy saving CO2 PSA process using hydrophobic adsorbents

Development Themes

Development of an energy saving CO2 PSA process using hydrophobic adsorbents

Zeolites have attracted considerable interest because of their narrow and uniform pore sizes, high surface areas, adjustable hydrophobic/hydrophilic balance, ion exchange capacity and acidity. Because of the high selectivity of various zeolites for CO2, they are frequently used in PSA systems. However, zeolites with high aluminum content, such as Zeolite 13X, become poor adsorbents in the presence of steam because of their high affinity for H2O. Recently, RITE has developed several types of all-silica zeolites that are unaffected by steam, and the CO2 adsorption properties of these materials under high pressure conditions in mixed gas systems are currently being evaluated.

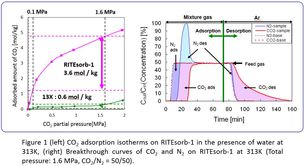

The all-silica zeolite RITEsorb-1 has a significant capacity for CO2 absorption, superior to that of Zeolite 13X in the presence of steam. Its CO2 uptake also increases sharply at a CO2 partial pressure of 1.6 MPa and its effective CO2 adsorption capacity has been estimated at 3.6 mol/kg, a value that is considerably higher than those of other adsorbents (Figure 1). The CO2 adsorption capacity of RITEsorb-1 is also comparable to the capacities of standard zeolites under dry conditions, even when it is pre-treated with saturated H2O vapor. Moreover, we have confirmed that RITEsorb-1 is a separable adsorbent with high selectivity for CO2 from a CO2/N2 gas mixture.

Click images to enlarge.